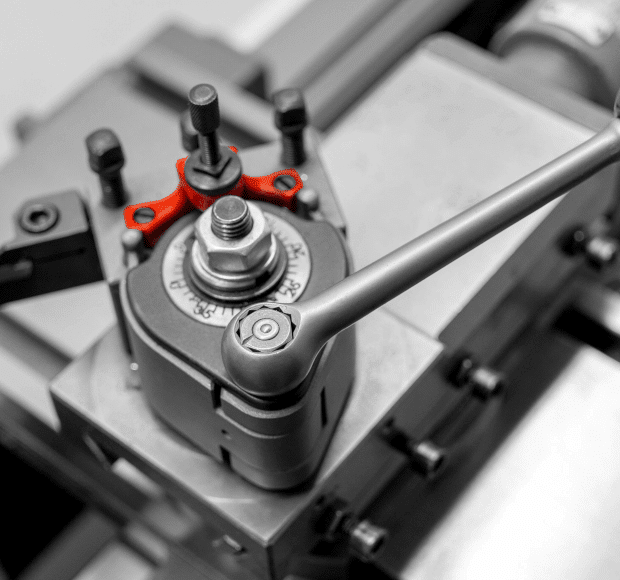

We manufacture your precision parts using state-of-the-art laser technology – from sample parts to individual pieces and series production. Over 25 machines with various laser sources enable us to precisely process a wide range of materials. Certified quality management ensures the consistently high quality of your components.

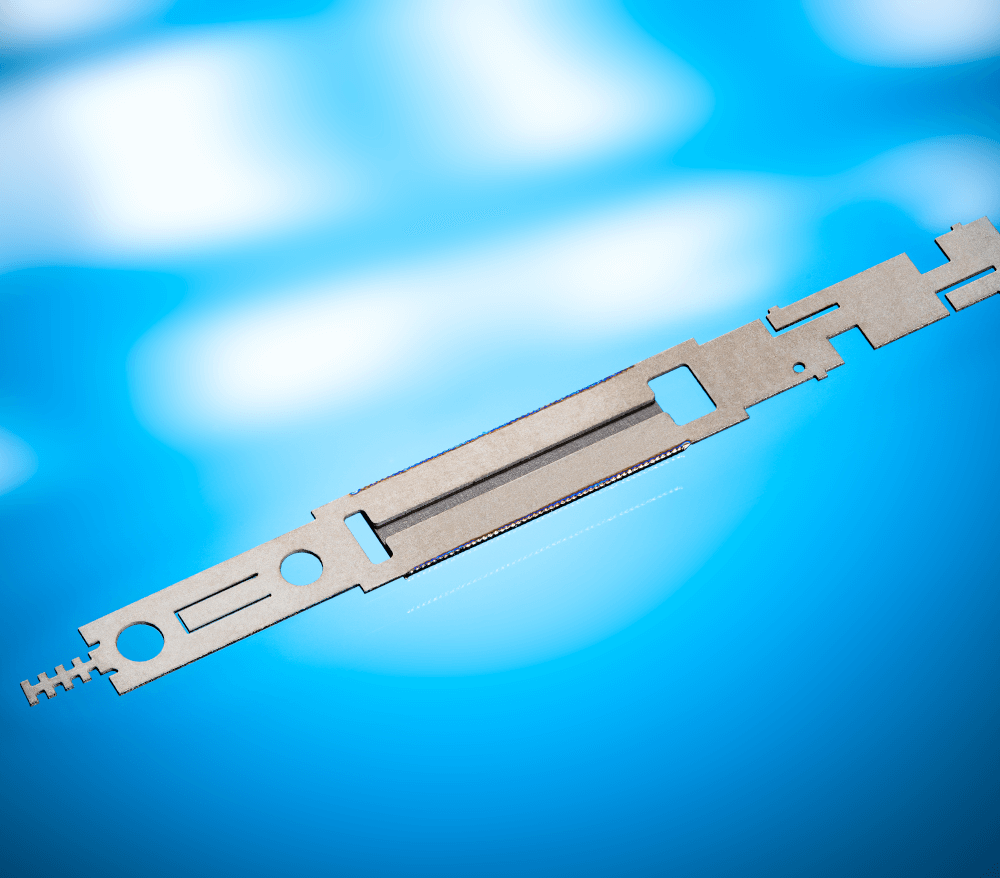

We manufacture high-precision 2D and 3D components using state-of-the-art laser technology. The use of different laser sources creates intricate contours and precise cutting patterns - ideal for demanding applications and complex geometries made of metal, polymers or ceramics.

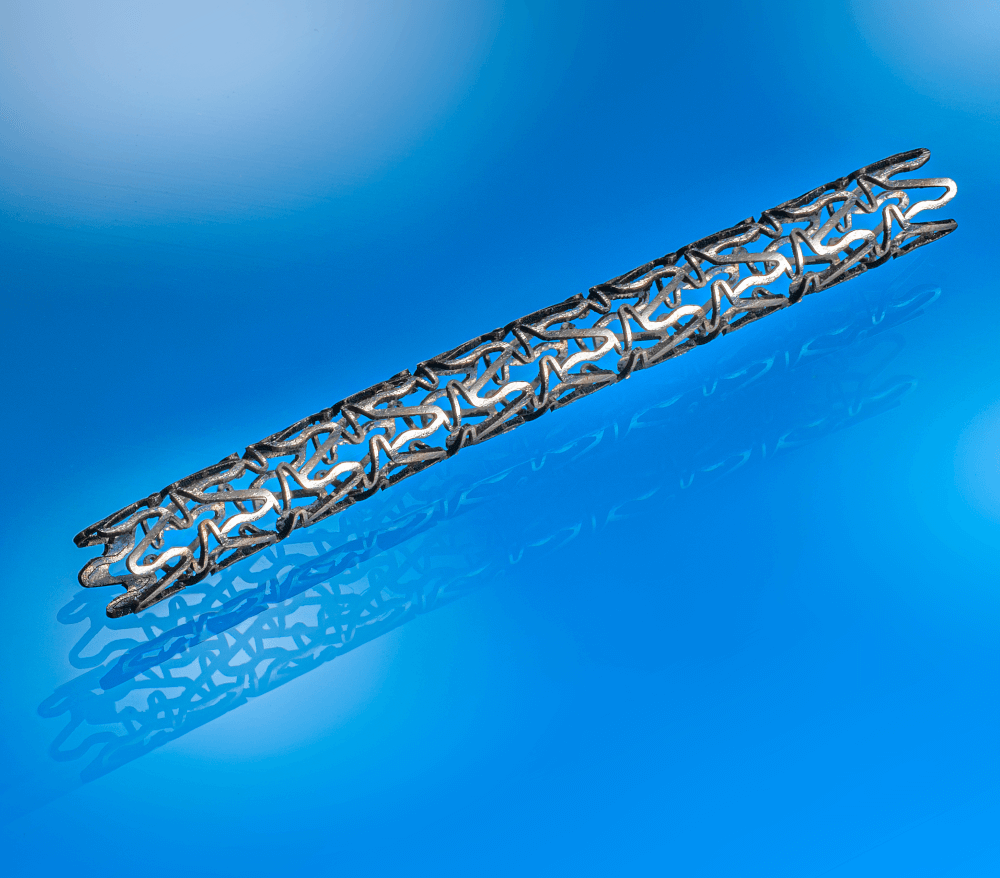

We manufacture precision tubes for various high-tech industries. Our contract manufacturing combines the latest laser technology with special expertise in the processing of tube components in order to produce the finest structures and tight tolerances with particular care.

Our customers benefit from the highest laser precision, reproducible quality and reliable processes. In contract manufacturing, we combine state-of-the-art technologies with many years of experience in micro material processing.

The result: precision parts that are technically convincing and economically manufactured.

more than

25

Years of experience

Have your precision parts manufactured by an experienced partner. With state-of-the-art laser technology, high process reliability and certified quality, we realize your requirements – efficiently, precisely and reliably.

For over a quarter of a century, we have been able to rely on the very high accuracy and quality of LLT Applikation's laser fineblanking and its punctual execution. We are happy to rely on the specialists at LLT Applikation for new developments and test designs.

In LLT Applikation, we have found a very important partner for us who has provided us with fast, cooperative and first-class support during the phase of a new technology introduction. Both the system quality and the service are still unbeatable after several years of operation.

The customer service and communication with those responsible is exceptional. The technical purchasing staff and the production team at LLT Applikation are always friendly and very competent when it comes to coordinating technical details. We look forward to continuing our good cooperation.

We value LLT Applikation as a reliable and competent partner for the provision of precision components. The cooperation is characterized by partnership-based communication and the fast, solution-oriented implementation of our tasks. The quality of the components supplied contributes significantly to the success of our projects.

We have valued the LLT Applikation for our fine laser parts for many years. Precision, flexibility, adherence to deadlines and the pleasant contact have convinced us right from the start.

We have been working with LLT Applikation for many years and greatly appreciate the consistently reliable and constructive cooperation. We would particularly like to emphasize the professional competence of our contacts, who impress with their technical know-how and quick response times. For us, LLT is a reliable business partner that we can always count on.

Our contract manufacturing department produces 2D and 3D precision parts with maximum dimensional accuracy. In addition to classic two-dimensional flat components, we also process complex three-dimensional geometries for a wide range of industries. Thanks to the latest

laser cutting, drilling, ablation and welding technologies

, intricate contours with cutting gaps of up to 10 µm are created.

We process foils and thin sheets with material thicknesses from 5 µm to 3 mm and thus cover a wide range of materials. Depending on the material and component size, we adapt the process individually to achieve precise results and optimum surfaces. From feasibility testing to prototypes and series production, we offer a reliable complete service for your precision parts.

We manufacture your precision tubes with the highest accuracy – from simple cutting to length to complex contour processing. Our contract manufacturing enables us to process tube lengths of up to 5 m, diameters of 0.3 mm to 16 mm and wall thicknesses of up to 3 mm. We process a wide range of materials – from stainless steel, titanium and copper to special metals such as nitinol or tantalum, plastics, ceramics and composite materials. From prototypes and one-offs to small or large series, we offer you the complete service package: feasibility testing, material procurement, fixture construction, laser processing and post-treatment – all from a single source.

Even after high-precision laser processing of your precision parts, we take care of the complete post-treatment – so that you receive a result that is ready for immediate use. We offer chemical processes such as pickling, electropolishing or deburring to remove discoloration and residues and to protect against corrosion and nucleation. Mechanical processes such as industrial ultrasonic cleaning or programmed bending machines allow even complex components to be finished. Laser finishing is also available, including marking with barcodes or data matrix codes, laser structuring to optimize surface and function and engraving of logos and serial numbers. With us, there is no need to search for other service providers – we supply you with precision components including finishing in a continuous process.

We support you in the cost-effective manufacture of your products and accompany you from your initial product idea through process development and series production in our company to your own laser production system.

Laser deposition manufacturing enables non-contact, material-friendly processing with maximum precision. In contrast to machining processes, no tools are required, which eliminates deformation and tool wear. Complex geometries with minimal tolerances can be realized, especially in 3D laser cutting and tube laser cutting. This results in laser parts with precise dimensional accuracy and outstanding surface quality - ideal for micro components, foils and thin sheets.

Ultra-short pulse lasers enable extremely fine processing in 3D laser cutting without any thermal influence on adjacent areas. The "cold ablation" produces smooth cutting edges and structures accurate to the micrometer, even with temperature-sensitive materials. This technology ensures that laser parts are produced with maximum precision, minimum roughness and maximum repeat accuracy - perfect for demanding applications in medical technology, sensor technology and research.

Yes, we process both supplied primary materials and customer-specific materials. Whether for tube laser cutting, 3D laser cutting or the production of complex laser parts - the decisive factor is the precise adjustment of the laser parameters to the respective material. This enables us to achieve optimum results with metals, plastics, foils and special alloys.

Yes, in laser job production we offer precise laser marking for laser parts of all kinds. Serial numbers, DataMatrix or QR codes are applied in a permanent, high-contrast and forgery-proof manner - even on components that were previously manufactured using 3D laser cutting or tube laser cutting. This enables end-to-end traceability and clear product identification.

Whether you have an inquiry, feedback or advice – write to us, we will be happy to help you.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information