Homepage / Applications / Precision drilling

LASER PRECISION DRILLING – SUPER FAST WITH MINIMAL WEAR

In addition to the wide range of possibilities, the high accuracy and repeatability as well as the enormous speed, laser drilling has another key benefit: The laser works almost wear-free.

PROCESS – WEAR-FREE DRILLING WITHOUT CHIPS

Up to 1,000 drill holes per second even in hard-to-reach positions

Up to 5 µm hole diameter

Wear-free tool

No need for post-treatment

Scope of Service

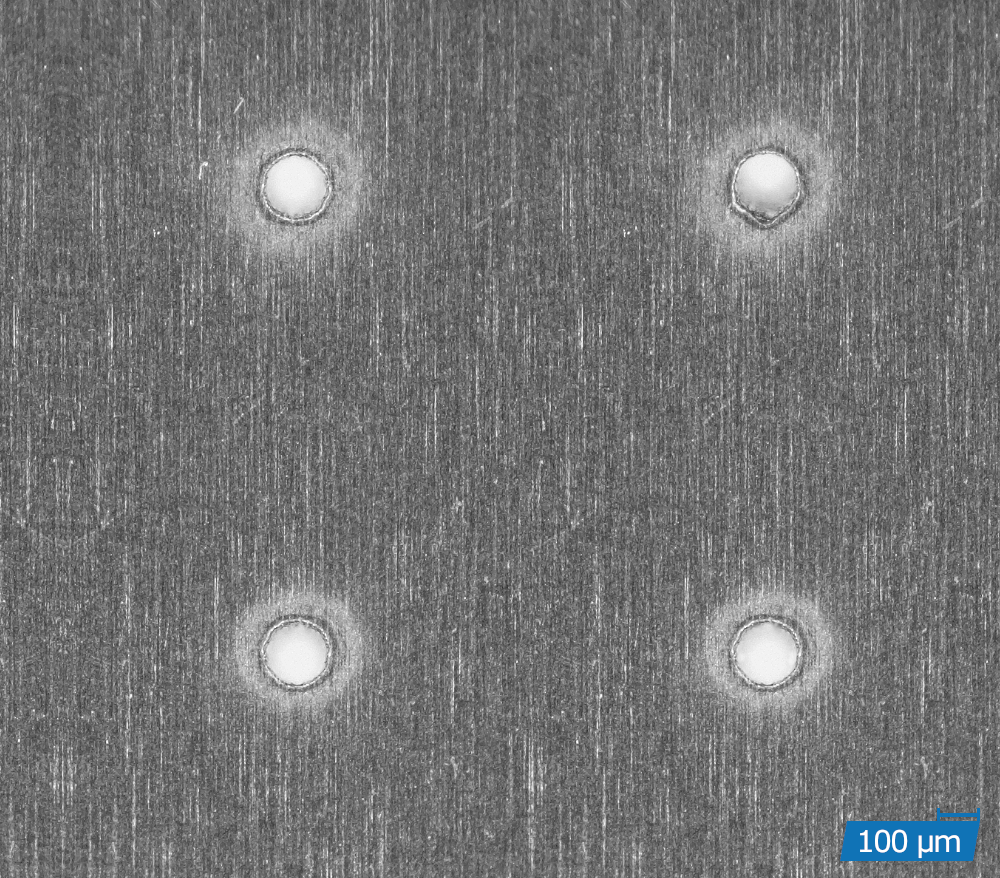

Single pulse process

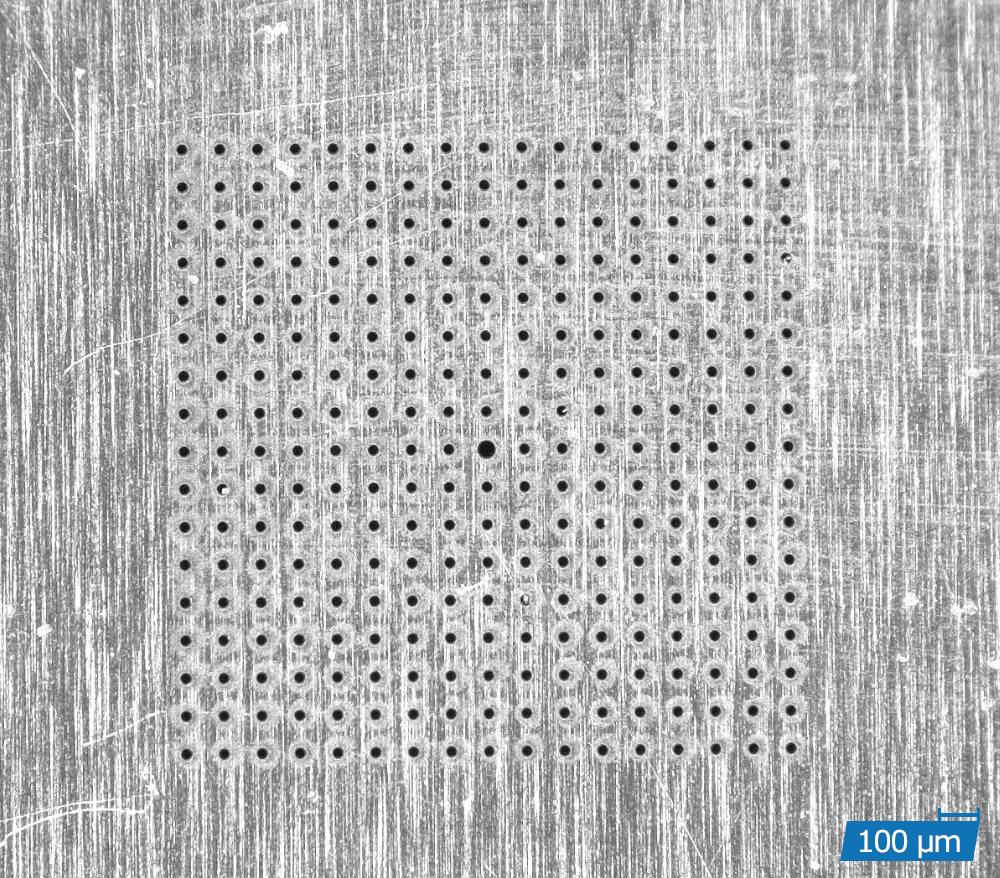

Percussion process

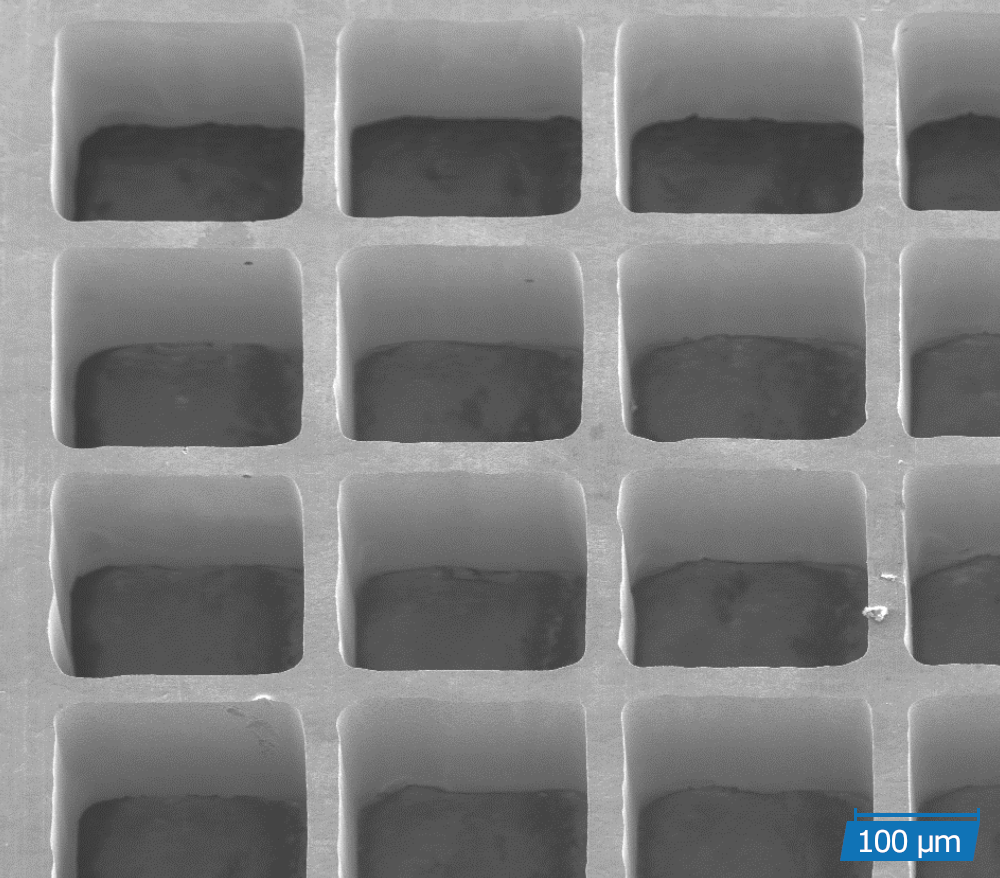

Trepanning process

APPLICATION EXAMPLES

Single pulse process

Trepanning process

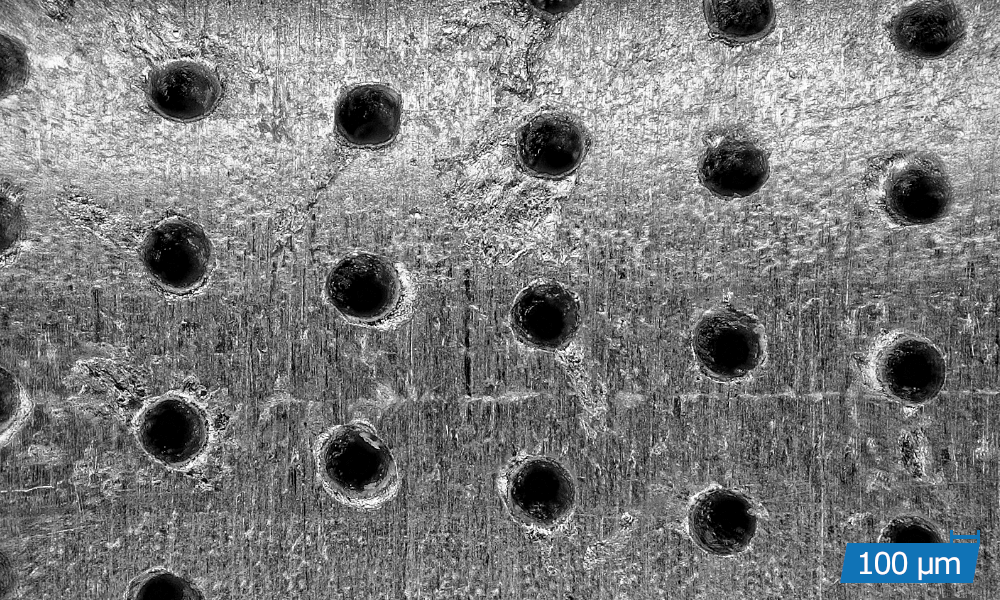

Thanks to the process gas, the melted material is blown out through the exit side of the hole.