Homepage / Applications / Precision ablation

Laser precision ablation – "COLD" PROCESSING OF VARIOUS MATERIALS.

Laser ablation also describes the layer-by-layer removal of material from component surfaces. The non-contact process is used in a variety of ways today, for example to mark or engrave components or products made of a wide range of materials and to structure surfaces in order to enhance them functionally or decoratively. The laser is increasingly replacing mechanical processes as a tool.

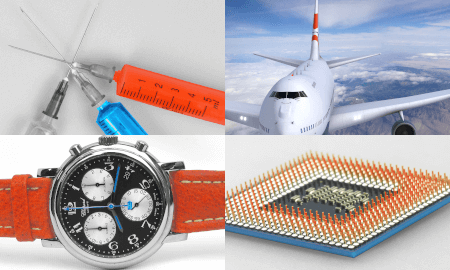

Especially in industries such as medical technology or the watch and jewelry industry, precision ablation with laser technology is used in many ways. But laser ablation is also used in tool and machine construction or in the automotive industry.

PROCESS - LAYER-BY-LAYER REMOVAL WITHOUT RESIDUES

In laser ablation, material is vaporized layer by layer. The ablated layer thicknesses are in the range of a few nm to a few µm. The process also allows thicker materials to be processed. Due to the low heat input, this process is also referred to as cold processing. The thermal stress for the component is minimal. The use of femtosecond lasers also prevents residues in the form of melt on the component surface. In addition, the ultrashort pulse laser enables the processing of special materials such as glass.

Fast and precise, gentle on the material and residue-free

Suitable for special materials and larger material thicknesses

Suitable for complex component geometries

Forgery-proof labeling and marking

Scope of Service

Process variants

Structure

Structuring typically involves changing the properties of surfaces in a targeted manner and improving them depending on the intended use. The objectives can be quite different. In principle, we distinguish between functional and decorative optimization. For example, machining can be aimed at influencing the sliding or wetting properties of a surface in order to reduce the wear of tools or to increase static friction. On the other hand, medical surgical instruments, for example, are laser-structured to avoid reflections.

The machining of products in the watch or jewelry industry, on the other hand, is primarily concerned with the decorative optimization of surfaces for fashion or aesthetic reasons.

Labeling / Marking

Similar to structuring, laser marking also provides an optical or functional enhancement of surfaces.

As a rule, labeling or marking serves to clearly identify components. For example, bar codes or data matrix codes are used to make products or components traceable.

But of course, products from the jewelry or watchmaking industry can also be given a decorative upgrade by adding lettering or motifs.

A special form of marking is "tempering". This process is characterized by the fact that no material removal takes place. Instead, a color change takes place as a result of a structural change, as with so-called "black marking" or "white marking". The corrosion resistance is not negatively affected.

Engraving / Scoring

Laser engraving also removes material layer by layer. This means that characters, logos or images can also be engraved into very hard materials such as glass or ceramics.

Particularly in the case of deep engraving, the difference from marking is primarily the depth of the structures introduced. The resulting surfaces are smooth and the cut edges are burr-free.

A special form of engraving is the so-called scribing. This involves the creation of predetermined breaking points by engraving deep structures into hard and brittle surfaces.