Homepage / Laser Systems / LLT.micro

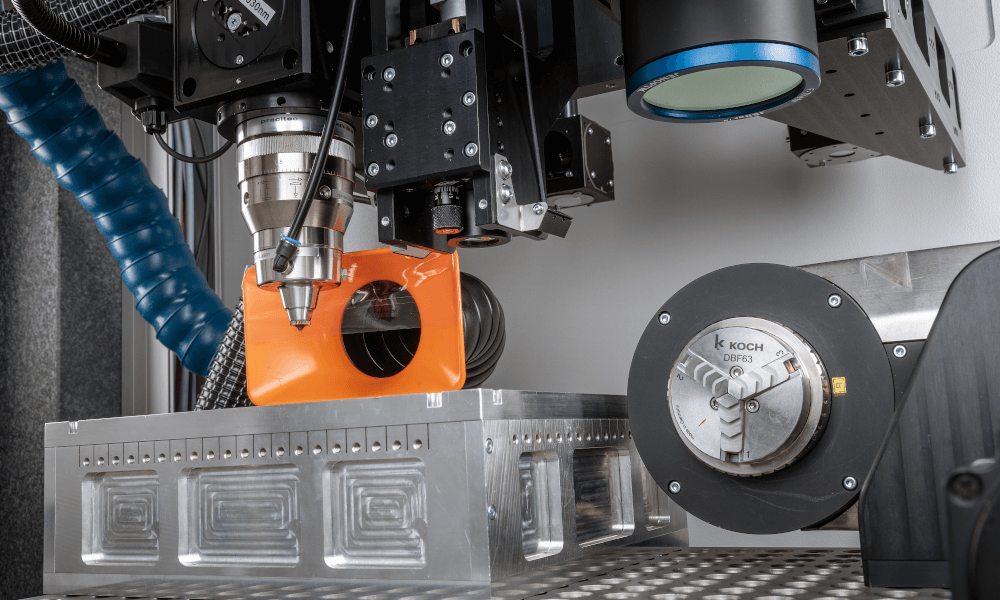

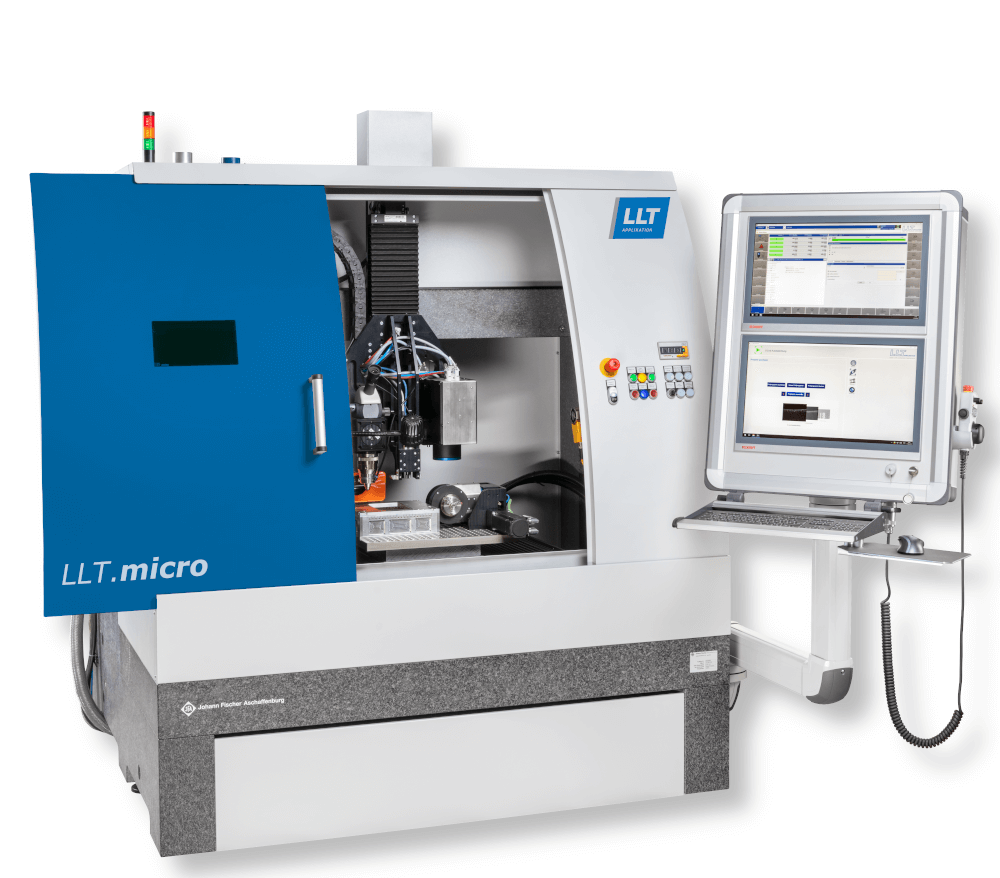

LLT.micro - HIGH PRECISION, UNIVERSAL & MATERIAL FRIENDLY LASER MICROMACHINING

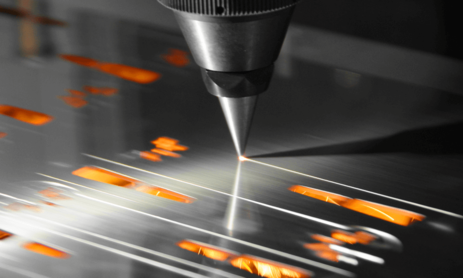

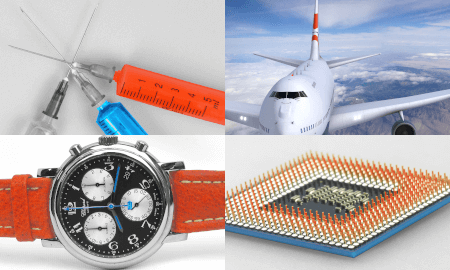

Laser micromachining is not just about the economic production of very small components. High-precision and gentle processing of sensitive products and materials is also important when it comes to quality criteria in medical technology, microelectronics or the jewelry industry. High-quality and burr-free cut edges are just as essential as the output quantity.

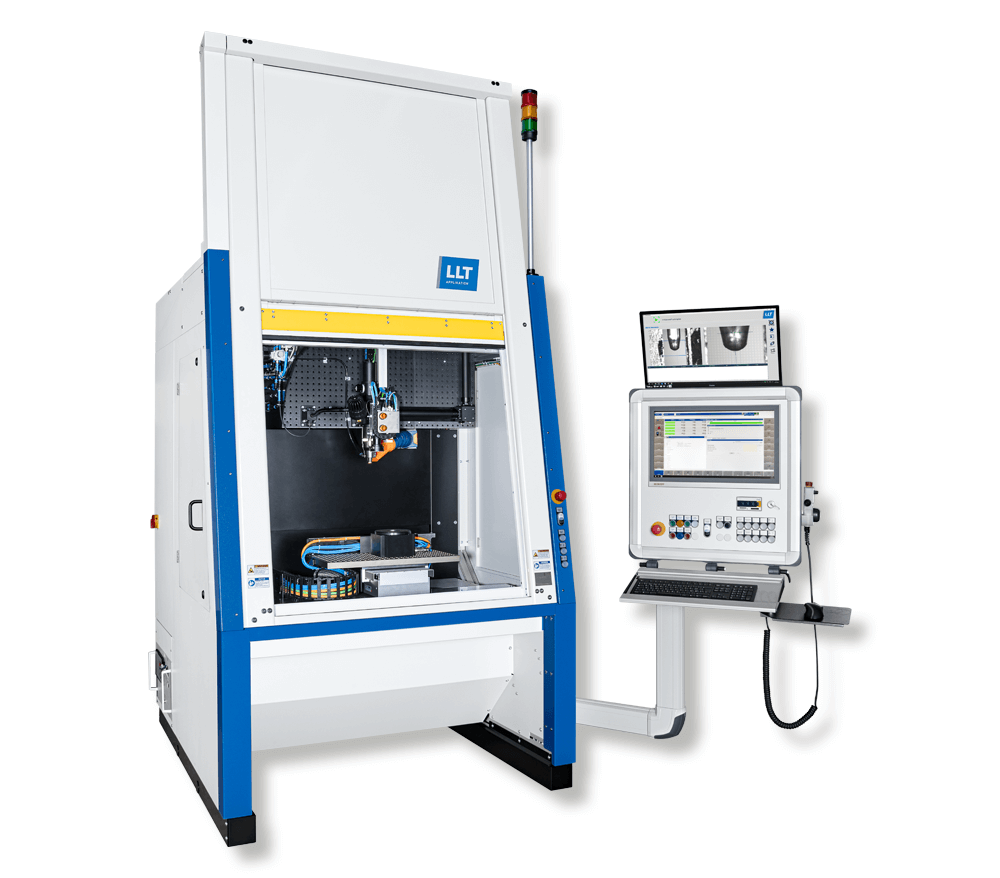

LLT.micro integrates modularity and technologies to meet these challenges. The compact system combines positioning accuracies of up to ± 3 µm and highly dynamic direct drives with efficient fiber lasers and gentle ultra-short pulse lasers.

Download Datasheet „LLT.micro“ ![]()

Highlights

Micro cutting, welding, drilling, ablating

Up to ± 3 µm positioning accuracy

Laser micromachining of 2D, 3D and cylindrical components

Process area (X, Y, Z): up to 500 mm x 500 mm x 400 mm

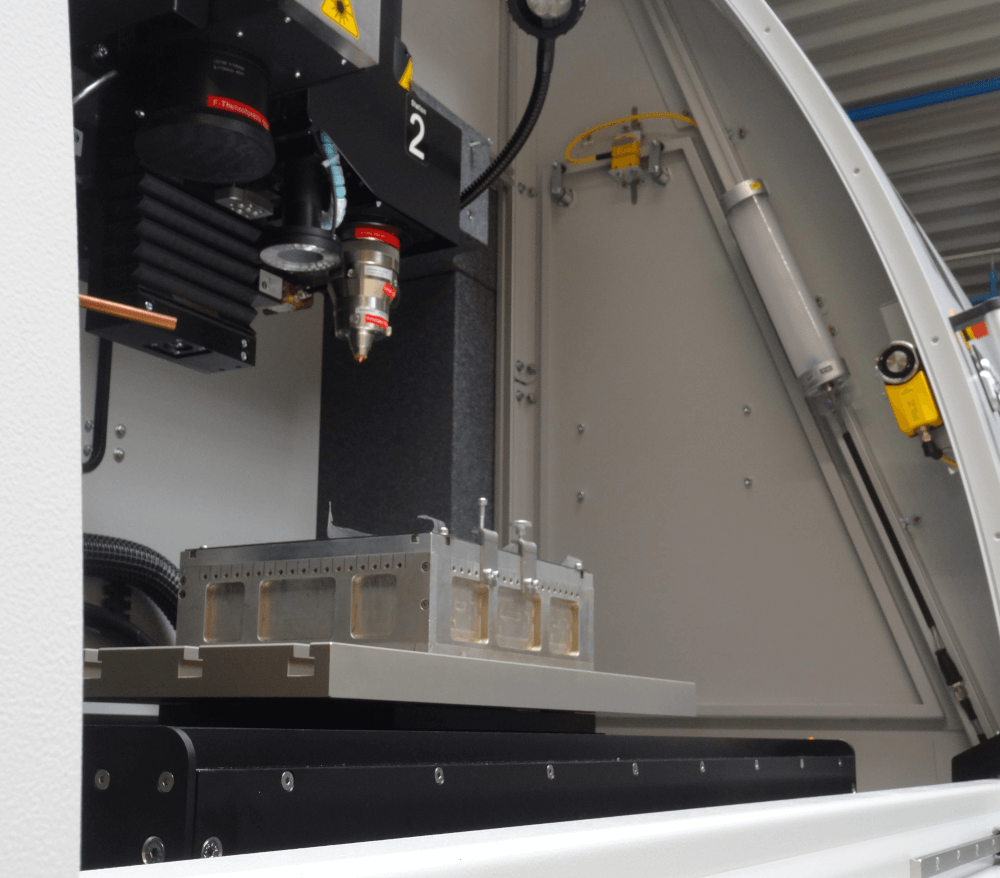

Fiber and femtosecond laser with fixed optics and galvo scanner

Highest precision and dynamics for excellent machining results

Wide range of applications for cutting, welding, drilling and structuring processes

APPLICATIONS FOR LLT.micro

SPECIFICATION

Standard wavelengths: 515 nm; 1030 nm

Galvo-scanner (in combination with fixed optics possible),

Drilling optics

Tilt and swivel axis module,

Motorized swiveling processing head

Options

Combination of fiber laser and femtosecond laser

Combination of fixed optics and galvo scanner

Integration of rotary, tilting, swiveling axes and motorized swiveling machining head

Vision system for automatic measurement and inspection

Intuitive design of weld paths on live image

Pneumatic clamping systems and automatic component handling

Filter and cooling systems

Control System & Software

BECKHOFF CNC controller

Ergonomic 22" dual touch screen user interface

Handheld control unit for setup work and manual positioning

Programming on the machine or at the computer workstation

CAD-CAM software for CNC programming