Homepage / Laser Systems / LLT.custom

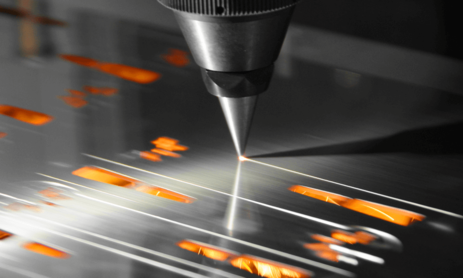

LLT.custom – TAILORED, SOPHISTICATED & OPTIMIZED LASER MICROMACHINING

Despite the wide range of configuration options for our series machines, planned budgets, specific manufacturing conditions or special process parameters can be reasons for special customer requirements. In this case, our team develops and manufactures customized machine solutions for laser precision machining. Of course, the optimized laser process is included.

Each customized machine of the LLT.custom series is the result of our many years of expertise in the field of laser micromachining. Not only the work as a contract manufacturer for precision products, but also the development and production of our own standard systems are the basis for ensuring that every machine delivers perfect machining results through the use of the latest technologies and is optimized for industrial use.

Download Datasheet „LLT.custom“ ![]()

Expertise - Benefit from our experience as machine builder

Since 1997, LLT Applikation has been dedicated to the use of laser technology for high-precision material machining. The knowledge and experience from this long period are also reflected in our machines and have a direct impact on the precision products of our customers.

More than 25 years of technological know-how in the field of laser micromachining

Experience with laser technology and reliable standard components in our own contract manufacturing

From design to feasibility study and sample production to the production-ready bundle of laser process and machine

Realized machines

Laser structuring machine (2019)

Application: Laser ablating

Laser: Femtosecond laser with galvo scanner and fixed optics

Purpose: Material abrasion of optical 3D parts

Customer: Research institution, Baden-Württemberg (Germany)

Features:

Three separate processing stations for machining with galvo scanner and fixed optics

Larger process area of 800 mm * 250 mm * 400 mm

5-axis processing

Three additional optical Z-axes for highly dynamic focusing

Three wavelengths (UV / Green / Infrared)

Measuring camera and measuring probe

Laser welding machine (2018)

Application: Laser welding

Laser: Fiber laser with fixed optics

Purpose: Contract manufacturing of medical technology manufacturers

Customer: Manufacturing service provider, Switzerland

Features:

Better accessibility to process area

Safety light barrier (Light curtain)

Fully integrated electrical cabinet

Designed as stand or seated workstation

Laser welding system (2017)

Application: Laser welding

Laser: Fiber laser with galvo scanner

Purpose: Welding of thin sheets

Customer: Manufacturer of thin sheet metal parts, Baden-Württemberg (Germany)

Features:

Customized machine frame

Gantry system

Rotating shuttle table (180°)

Safety light barrier (Light curtain)

Design and manufacture of fixtures for pre-assembly and pneumatic clamping