Homepage / Applications / Precision welding

LASER PRECISION WELDING - HIGHEST CONNECTIONS WITHOUT ADDITIONAL MATERIALS

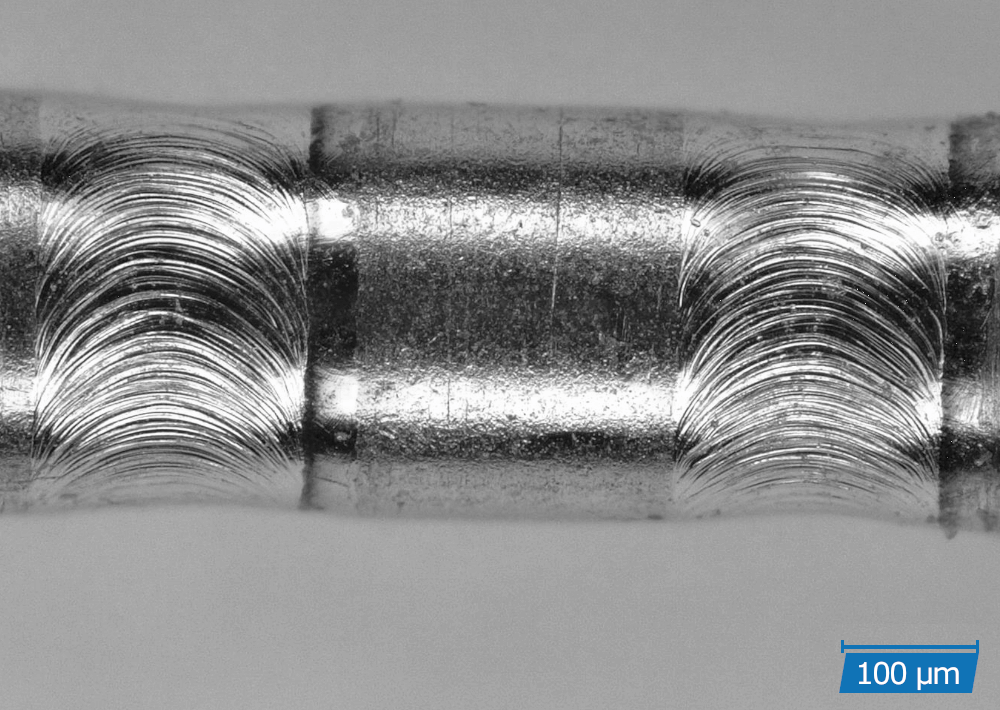

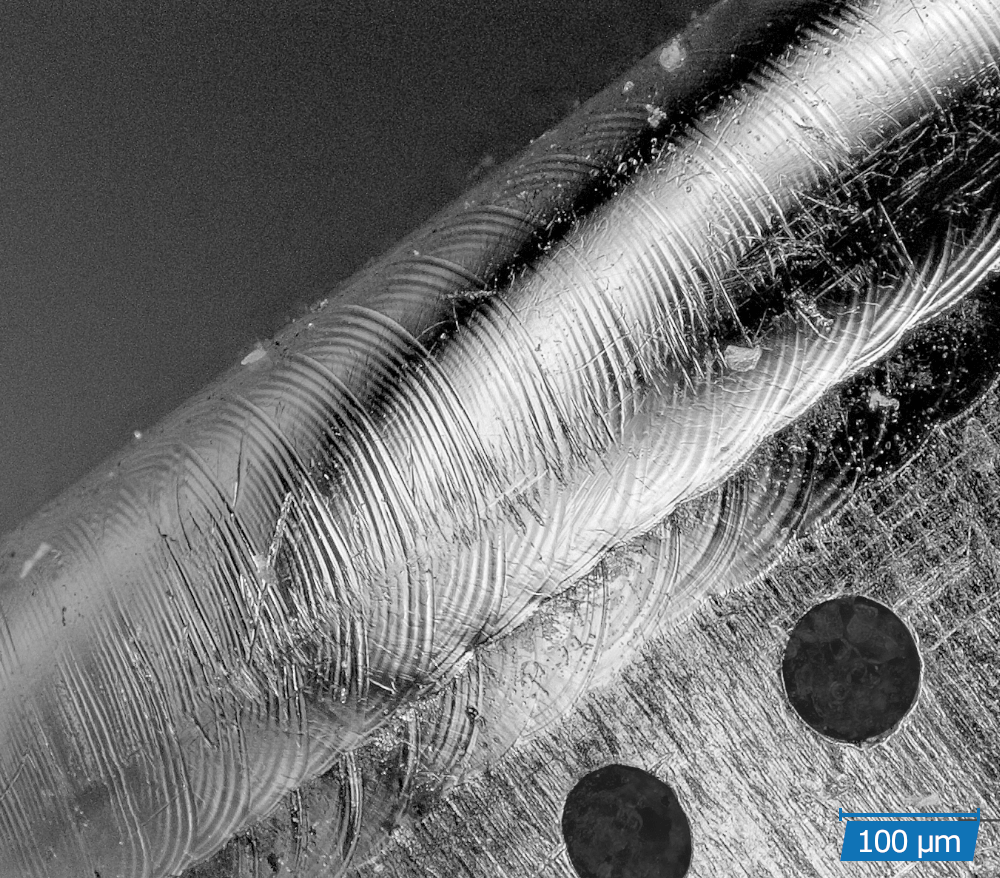

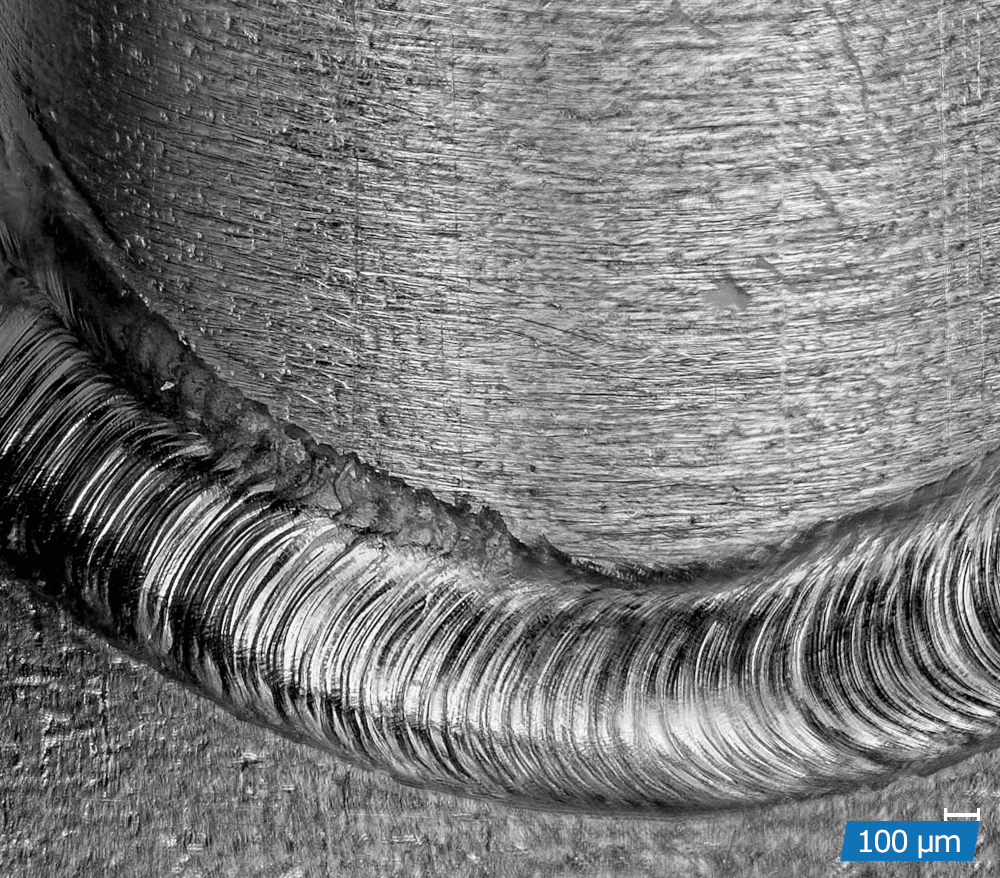

Laser precision welding is a modern joining process and enables very fine weld spots or seams with high strength and tightness due to the highly focused laser radiation.

Due to the high power density in the focus, the very short process times and the energy supply that can be precisely dosed via laser parameters, even material combinations that are conventionally difficult to weld can be successfully joined with lasers.

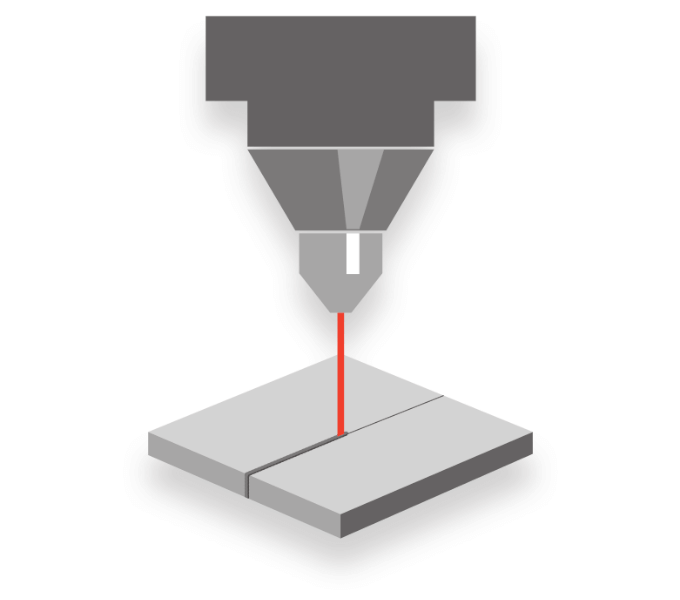

PROCESS - HEAT CONDUCTION OR KEYHOLE

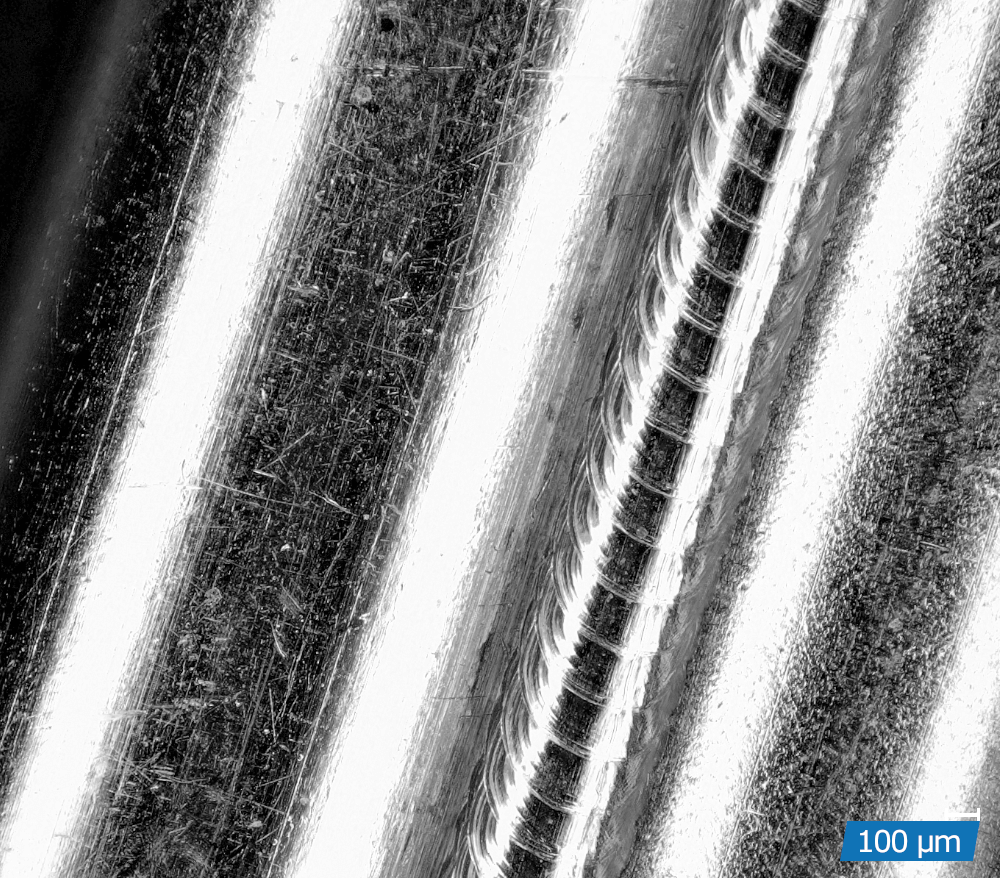

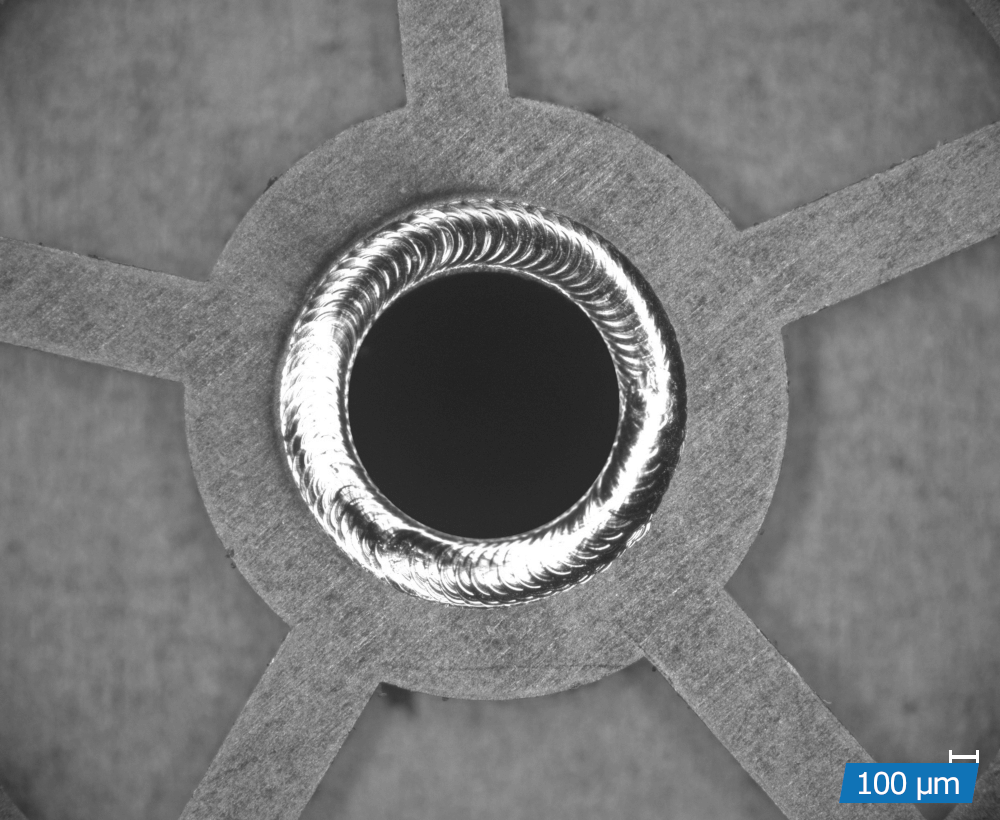

Laser precision welding uses a focused laser beam as the energy source. The joining partners are firmly joined by a relative movement between the laser beam and the workpiece. The processing procedure takes place under inert gas, such as argon or nitrogen, which prevents oxidation of the component surfaces. Depending on the process gas, material and laser parameters, the joining process is often determined by pure heat conduction, and in deep welding applications by the so-called keyhole effect.

Micrometer-precise, high-strength connections

With or without additional material

Minimum heat input

No structural changes

Suitable for special material combinations

Scope of Service

When classic welding methods reach their limits, we can help you with our laser systems and our contract manufacturing. For 2D and 3D components as well as for cylindrical precision components, different welding seams and geometries with up to 2 mm welding depths can be realized using the following processes:

Spot welding

Seam welding

Which laser equipment is ultimately used depends, of course, largely on the geometry of your components and your specific requirements.

Materials

One of the distinguishing features of laser precision welding is that it can also be used to join more specialized material combinations.

We can weld the following materials for you:

Titanium

Nickel

Nickel

Stainless steel

Aluminum

Copper

You would like to weld other materials? Then please feel free to contact us.