Homepage / Laser Systems / LLT.preci

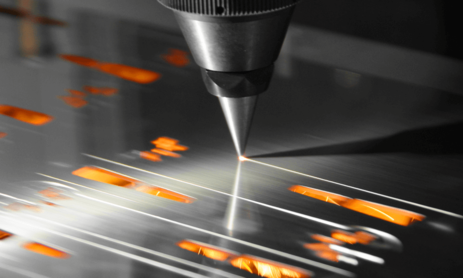

LLT.preci - PRECISE, RELIABLE & FLEXIBLE LASER MICROMACHINING

No matter what specific industry, reliable machine solutions are required in industrial manufacturing environments. This also counts for laser precision machining. A special challenge is the combination of robustness of the production equipment and the accuracy of the machining results. Added to this is the required cost-effectiveness of the technology used.

LLT.preci offers a reliable machine concept that meets these high demands. By combining the fiber laser with scanner optics, the basic 3-axis machine can operate simultaneously with up to seven axes. Despite compact external dimensions, the large machining area can be scaled to up to 500 mm x 500 mm x 300 mm, depending on specific customer requirements.

Download Datasheet „LLT.preci“ ![]()

Highlights

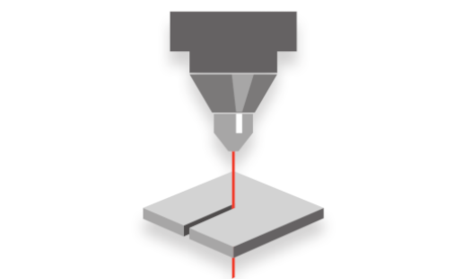

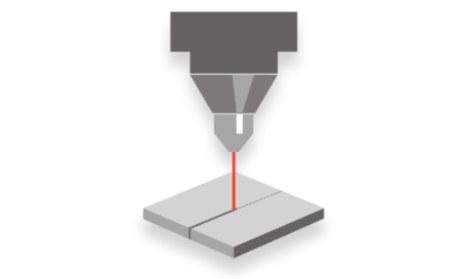

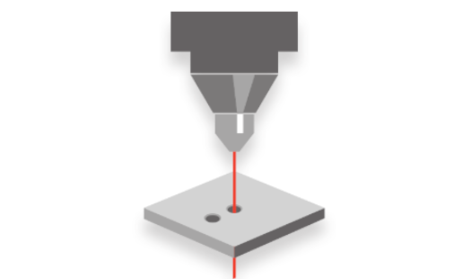

Micro cutting, welding, drilling

Up to ± 10 µm positioning accuracy

Laser micromachining of 2D, 3D and cylindrical components

Process area (X, Y, Z): up to 500 mm x 500 mm x 300 mm

Fiber laser with fixed optics or galvo scanner

Most efficient laser machining with precision and dynamics

Reliable and robust fiber laser technology

Compact and universal machine concept

SPECIFICATION

Options

Integration of rotary, tilting, swiveling axes and motorized swiveling machining head

Vision system for automatic measurement and inspection

Intuitive design of weld paths on live image

Pneumatic clamping systems and automatic component handling

Filter and cooling systems

Control System & Software

ECKELMANN CNC controller

Ergonomic touch screen user interface

Handheld control unit for setup work and manual positioning

Programming on the machine or at the computer workstation

CAD-CAM software for CNC programming