Homepage / Laser systems

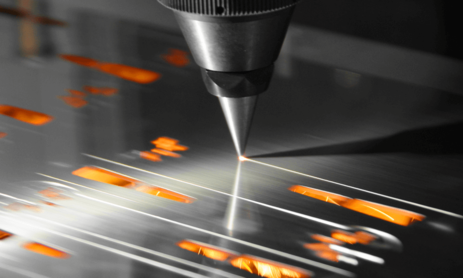

LASER SYSTEMS – NEW STANDARDS FOR HIGH-PRECISION LASER MICROMACHINING

We design and build your laser system! Whether standardized series system or individual special machine, thanks to our experience as a contract manufacturer, we know exactly what is important in a machine solution for the production of laser precision components. If necessary, we adapt our standard machines to your special requirements. And if that is not enough, we will develop and manufacture your very own individual machine.

LLT.micro

The machines from the LLT.micro series are some of the most accurate systems on the market. Thanks to air-bearing positioning systems, the systems achieve accuracies of up to ± 3 µm. Due to the combination of different laser sources and two parallel equipped processing heads, LLT.micro can cut, weld, drill and structure a wide variety of component geometries and materials.

LLT.preci

LLT.preci provides the solid and universal solution for laser processing of a wide variety of materials and geometries. Using fiber lasers, even larger material thicknesses can be easily cut, welded or drilled with positioning accuracies of up to ± 10 micrometers. The scalability paired with dynamics and precision makes the LLT.preci the price-performance winner.

LLT.tube

LLT.tube is the series machine for laser micromachining of fine and precision tubes with processing accuracies of up to ± 3 µm. With up to four axes, the machine processes cylindrical components with diameters from 0.3 mm to 19 mm and enables both radial and off-axis cuts. By connecting a fully automatic component feeder, LLT.tube can also operate autonomously.

LLT.custom

LLT.custom represents the customized system for laser micromachining from LLT Applikation. Whether machine frame, positioning system or laser source, depending on what the process requires or what specific goals the customer is targeting, a wide variety of standard components can be combined in such a way that the final precision system is highly accurate, gentle on the material and operates with maximum output.