Homepage / Laser Systems / LLT.tube

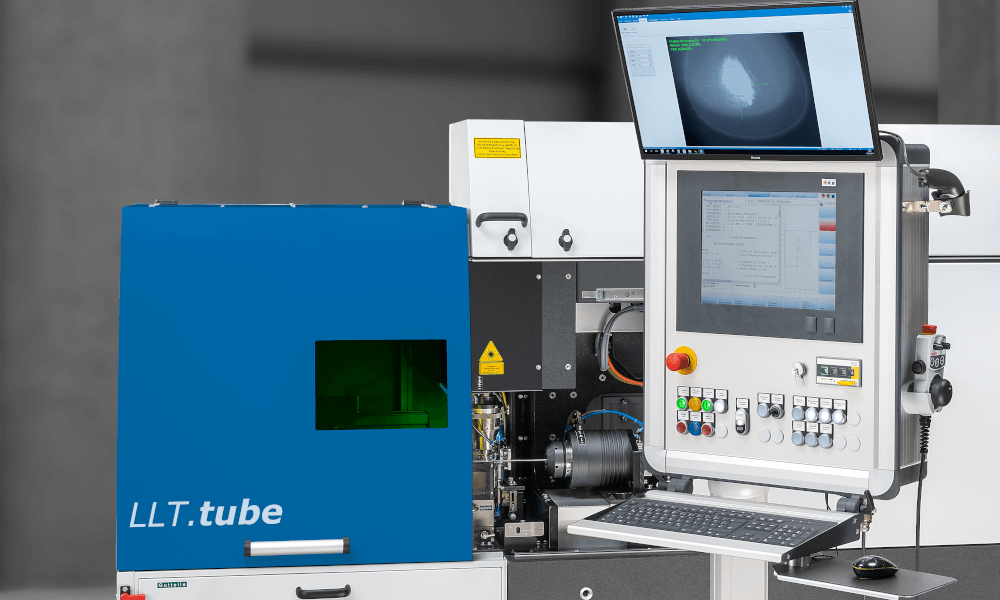

LLT.tube – FULLY AUTOMATED, MATERIAL FRIENDLY & µm-ACCURATELY LASER MICROMACHINING

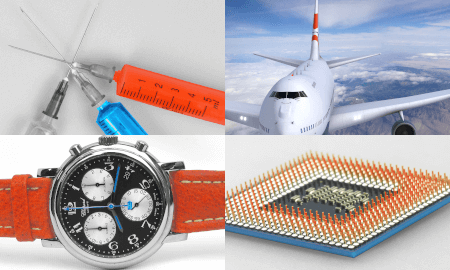

Challenges in manufacturing and processing fine or precision tubes are complex. Especially high-tech industries such as medical technology, sensor technology or optics, expect not only high precision but also gentle treatment of sensitive and cost-intensive materials, as in the case of stents or hypotubes.

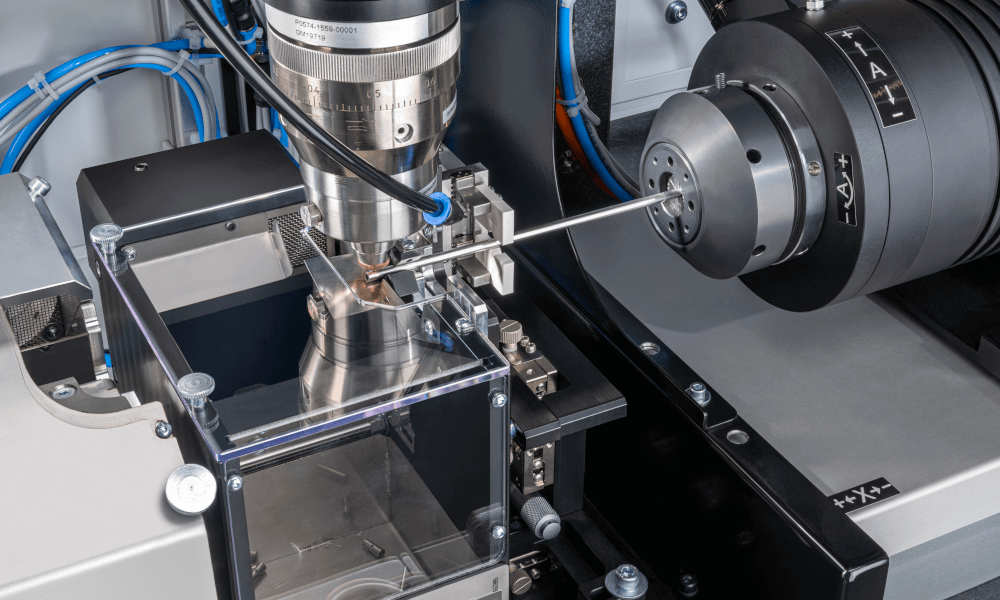

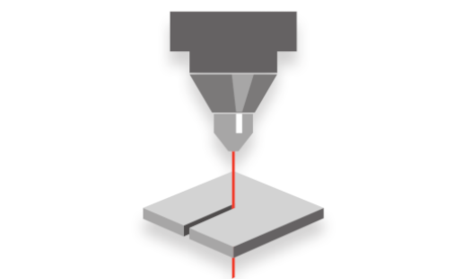

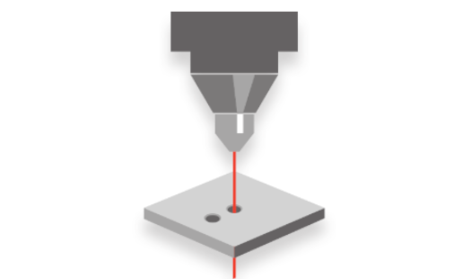

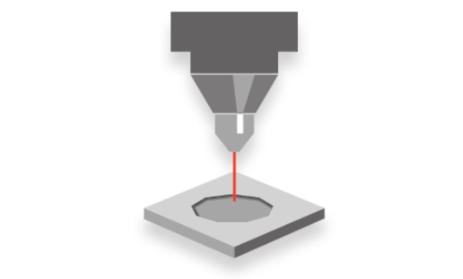

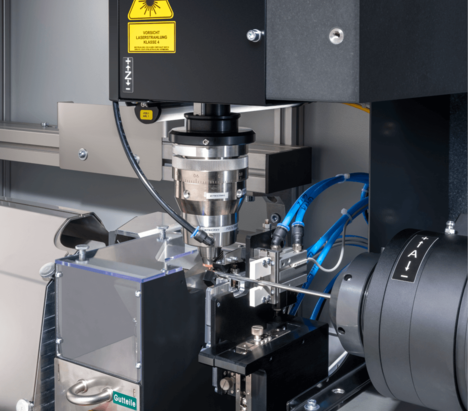

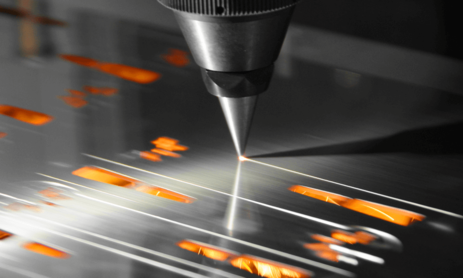

LLT.tube was developed to meet these expectations. Due to the use of an ultrashort pulse laser, the heat-affected zone and the associated thermal stress on the material are minimal, as are the feasible dimensions of the cutting or drilling contours. The material retains the desired properties and residues such as melt are avoided.

Download Datasheet „LLT.tube“ ![]()

Highlights

Microcutting, drilling and marking of fine tubes, cylindrical and 2D components

Up to ± 3 µm positioning accuracy

Process range (X, Y, Z): up to 600 mm * 50 mm * 35 mm

Bis zu 4 Achsen für radiale sowie Off-Axis-Schnitte

Combined operation of fiber and femtosecond laser

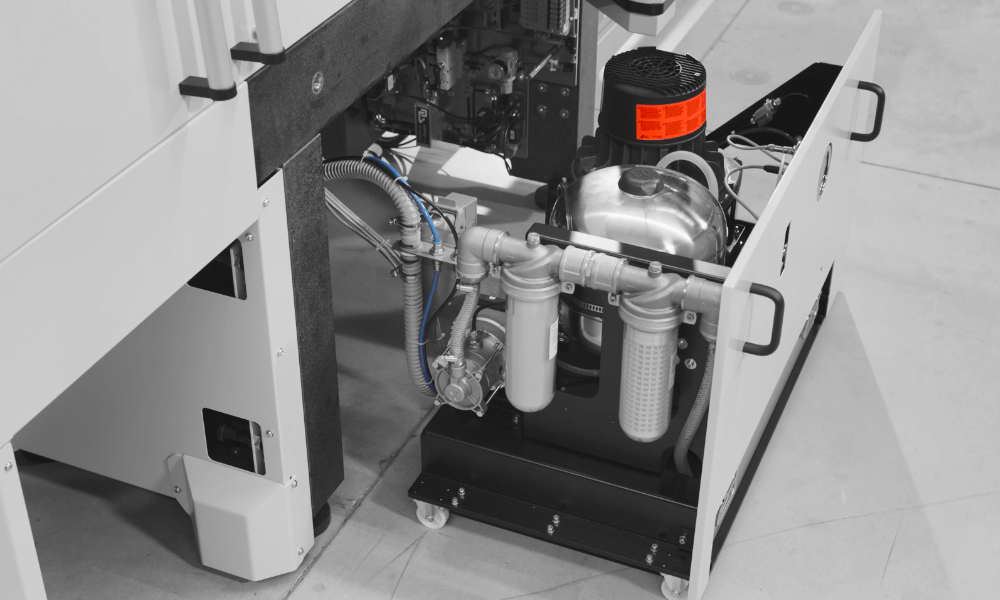

Tube feeder and wet cutting system

High precision laser machining of precision tubes

Gentle processing of sensitive and high-cost materials

Autonomous operation with fully automated component handling

SPECIFICATION

Options

Fully automated tube & bar feeding incl. unloading function

Fully integrated and closed water circuit for wet cutting applications

Finished part sorting

Vision system for automatic measurement and inspection

Fully integrated electrical cabinet

Pneumatic clamping systems and automatic component handling

Filter and cooling systems

Control System & Software

ECKELMANN CNC controller

Ergonomic touch screen user interface

Handheld control unit for setup work and manual positioning

Programming on the machine or at the computer workstation

CAD-CAM software for CNC programming