Homepage / Laser Job Shop / Aftercare

FINISHING – POST-TREATMENT OF PRECISION COMPONENTS

We finish your precision parts. Even with high-precision laser machining, post-treatment of processed components may be necessary to get a perfect finish. We do this final step for you. You save time and money and there is no need to find an additional service provider.

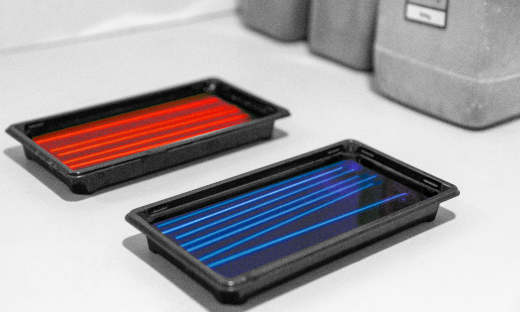

Chemical treatment

Deburring / Pickling / Electropolishing

Removal of residues and discolorations

Decorative enhancement of surfaces

Clean and burr-free cut edges

Protection against corrosion or oxidation

Protection from environmental influences

Protection against germs and contamination

Reduction of abrasion

As part of our laser job shop, we offer several methods to chemically post-treat and finish your lasermachined precision components.

For example, pickling is used to remove residues, discolorations or slag. In addition, the use of pickling agents enables burrs to be removed and protects the material surface from oxidation.

One process that is mainly used for medical technology products is electropolishing. The combination of current and electrolytes reduces the surface area of the material. This makes it harder for germs and bacteria to adhere.

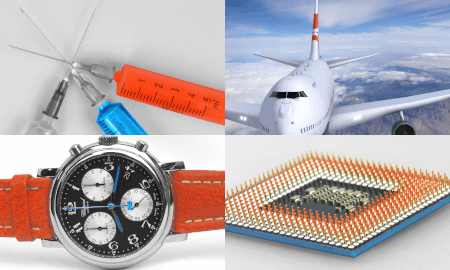

Mechanical treatment

Ultrasonic Cleaning / Metal Forming

Efficient cleaning of complex precision components

Effective removal of cutting residues

No need for aggressive chemicals

Cleaning of difficult to access component areas

Bending and folding of material thicknesses up to 1.5 mm

Bending machine for components up to max. 150 mm width

Minimum bending radius up to 0.2 mm

In addition to chemical treatment of precision components, we also provide mechanical treatment of your laser-processed products.

Especially for very small and sensitive components, such as stents or cannulas, our high-performance ultrasonic baths are perfect for removing residues and contamination from surfaces or for detaching material residues from the cut contours.

Furthermore, we use our programmable bending machine with an extensive tool set to form spring and contact elements or housings and covers after their laser production for customers from microelectronics or sensor technology.

Additional post-treatment methods we offer on request.

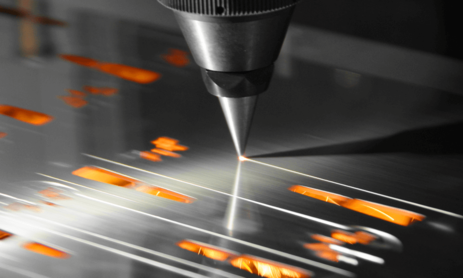

LASER TREATMENT

Marking / Structuring / Engraving

As an expert in the field of laser processing, the post-treatment and finishing of precision components using laser technology is also part of our portfolio.

Laser marking is used to visually enhance components, to make them identifiable, or to mark them with barcodes or DataMatrix codes for traceability purposes.

In addition, laser structuring is used to optimize the mechanical properties of surfaces. This improves, for example, the sliding properties or the interactions with other surfaces. A typical example from medical technology is the reduction of light reflection from instruments to make the surgeon's work easier.

Marking with barcodes, DataMatrix codes and serial numbers

Surface optimization with laser structure

Engraving of letters, logos or images

Processing of a wide range of components or carrier materials: type plates, laser foil labels, tools, implants, jewelry

Processing of standard materials: stainless steels, aluminum, titanium, ceramics, glass, plastics

Other treatments

Cooperation with local and regional partners

Countersinking

Thread cutting

Bending and folding of large component dimensions

In addition to the above-mentioned methods, we also offer other services in cooperation, such as countersinking or thread cutting. We also bend or fold components with larger dimensions or material thicknesses.

Due to our experience we can use a large network. In particular, we rely on local and regional partners. This gives us the possibility to use services on short notice. And as a positive side effect, we support the local industry.

You benefit from our high quality standards, short response and delivery times and fair prices. In addition, you avoid the expensive and time-consuming search for reliable and competent service providers.

You need a special treatment for your products? Do not hesitate to contact us.