Homepage / Industries

INDUSTRIES – HIGH-TECH IN EVERY SECTOR

Every industry has its own characteristics in terms of the purposes for which the products are used or the materials they are made of. Nevertheless, the customers of LLT Applikation have one thing in common. They all come from sectors that are characterised by particularly high demands on high-precision and gentle material machining. For this reason, these companies are often very technology driven. Because both their own standards and the competitive and regulatory requirements for the quality and safety of products are constantly evolving and therefore require innovative manufacturing solutions.

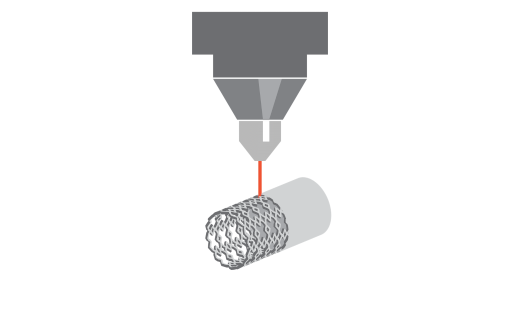

Medical Technology

There is no other market where industrial standards, product and process safety, precision and reliability play such an important role as in medical technology.

Operations should be performed with minimum injury to healthy tissue. Consequently, the dimensions of products such as vascular supports can be in the micrometre range. Therefore, precision machining with the use of laser technology has developed into a basic technology for cutting, welding, drilling or structuring microscopically small metallic and non-metallic components.

A selection of specific applications that have already been realised as part of our laser job shop or with our precision machines:

Laser precision cutting of stents, cannulas, needles or hypotubes

Laser precision welding of catheters and surgical instruments

Laser precision drilling of tubes, nozzles or filter elements

Laser precision structuring of surfaces of surgical instruments

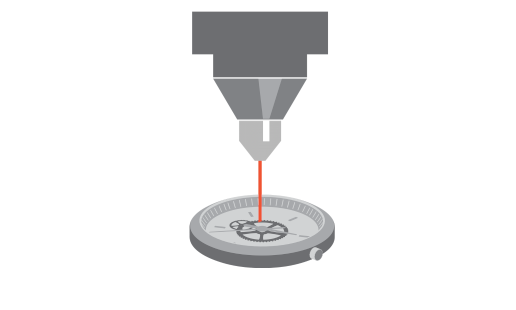

Watches & Jewelry

In addition to the standards for product and process safety, the watch and jewellery industry has unique requirements for precision, aesthetics and variety of materials for the smallest components.

This is where the laser can show its advantages over conventional processes. Very clean and parallel cutting edges as well as low surface roughness create a high optical value and quality. The flexibility of the laser allows the gentle processing of metals such as gold, platinum or durnico. In addition to cutting, drilling and structuring metallic materials, non-metallic materials such as ceramics or precious stones can also be processed.

A selection of specific applications that have already been realised as part of our laser job shop or with our precision machines:

Cutting of watch dials, gears and spring elements

Drilling of watch hands

Structuring and marking of watch cases and bracelets

Engraving jewelery

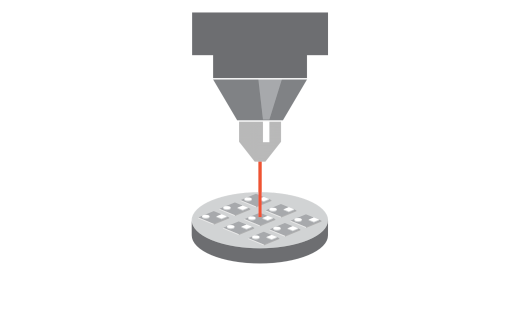

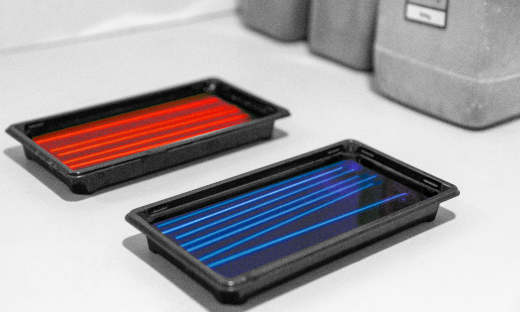

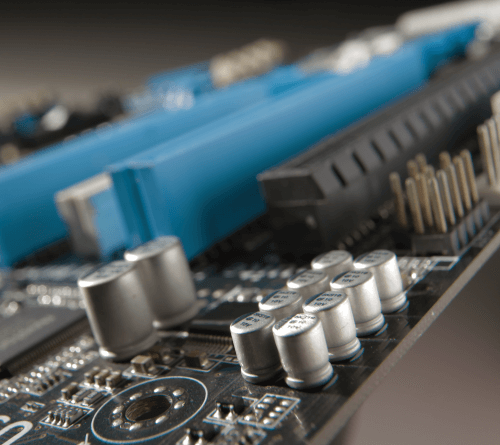

Electronics & Semiconductors

The ongoing trend for miniaturisation is constantly challenging electronics manufacturing. In particular, trends such as the IoT (Internet of Things) ensure that products have to combine increasingly extensive functions in more and more compact spaces. And competition also demands maximum economic efficiency in the manufacturing of products.

This is where flexible laser technology can play to its strengths, because it allows the µ-precise machining of a wide range of materials and geometries. The sensitive components are not affected by thermal stress and remain dimensionally stable.

In this way, electrical connections can be welded, printed circuit boards and ceramic foils can be cut or contacts in multilayer structures can be removed by laser without damaging surrounding layers. The laser also allows alternative surface processing of silicon wafers and can complement classic etching processes.

A selection of specific applications that have already been realised as part of our laser job shop or with our precision machines:

Cutting and welding of stator laminations or stator laminations packages for electromobility

Cutting contours from printed circuit boards, flex boards and ceramic foils

Welding of battery contacts and electronic housings

Removal of material and protective layers from circuit carriers

Drilling of ceramics

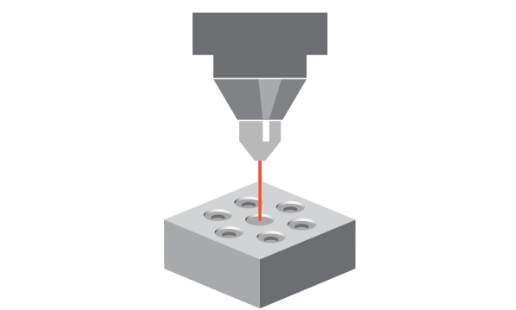

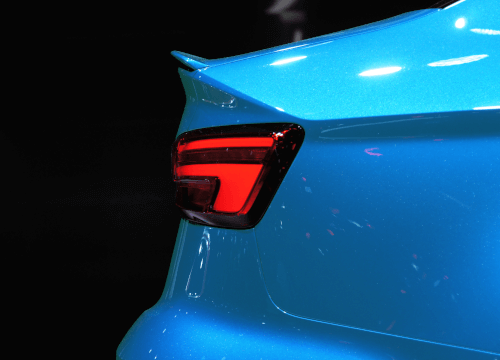

Automotive

In addition to medical technology, the automotive industry has the highest requirements in terms of compliance with industry standards as well as product and process safety. Furthermore, manufacturers and suppliers have to meet special requirements in terms of durability and service.

Due to the high complexity of modern vehicles, which continues to increase because of ongoing digitalisation, the possible applications of laser technology in the automotive sector are enormous. Whether it is injection nozzles for combustion engines or components for electric motors, lighting and electronics or the interior, laser micromachining is one of the central technologies for cutting, welding, drilling and structuring many different materials used in motor vehicles.

A selection of specific applications that have already been realised as part of our laser job shop or with our precision machines:

Structuring the surfaces of interior components to optimise friction properties

Layer-by-layer ablation of the material from lighting components

Welding electrical connections of light sources on flexible printed circuit boards for lighting components

Cutting and welding of components for electric motors

Cutting of heating elements for electric vehicles